AWFT132

Automatic pre-filter with backwash

The AWFT132 is an economic, efficient and reliable impurity filter. It can be widely used for water from public water supply systems, underground wells, factories, mining companies, etc. The filter can initially remove sand, rust flakes, scale, particles, slime and suspended solids, and effectively reduce contamination such as rust, turbidity, and bacteria proliferation in water pipes. Furthermore, it protects water utilizing household appliances such as washing machines, water kettles, dish washers, coffee machines as well as in-floor heating and central air conditioning systems.

The AWFT132 is a fully-automatic filter, which filters raw water continuously over a long period of time without requiring maintenance. The FT132 is durable, compact, convenient, and thus suitable for filtering water used at home and for industrial purposes. The FT132 is equipped with an electronically-controlled timing system, which starts cleaning automatically every 12, 24, 36 or 48 hours, for 30-100 seconds each time. It is also equipped with a pressure differential switch that monitors the pressure drop at all times. If the pressure drops to 0.5bar, the backwash will be started. This system allows for a thorough cleaning and prevents any possible clogging. TheAWFT132’s professional cleaning cycle is composed of a discharge system, a filter cartridge flushing system, and a high-speed water jet system. If the differential pressure exceeds 0.5bar or a pre-set time interval has elapsed, the engine will rotate 90 clockwise and automatically flush the bottom of the filter cartridge. The incoming water passes through central vessel, then enters the turbo-jet channel from where it is forced against the cartridge ensuring thorough cleaning of the filter cartridge. Additionally, the filter also features an output signal to control pumps, solenoid valves, alarms, etc.

- Automatic cleaning (time settable)

- Professional two-step cleaning

- Equipped with differential pressure switch

- 360°adjustable brass connection plate

- Resistant to high temperature and pressure

- Food-grade Stainless steel filter cartridge (alloy 304); no replacement required

- Brushes equipped with silver inserts to eliminate bacteria

- Manufactured in Italy

| Unit | Connection (Inch) |

Flow rate (m3/h) |

Pressure gauge | Pressure (bar) |

Filtration rating (micron) |

Inlet temperature (℃) |

Filter cartridge | Height*Width*Depth (mm) |

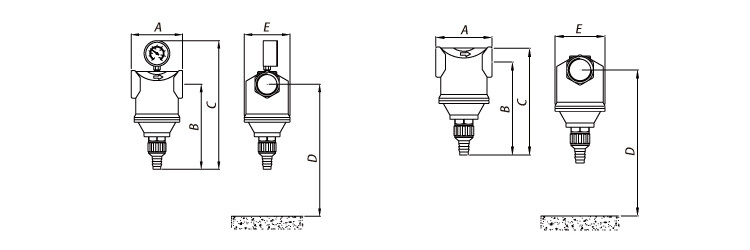

| FT132 | 1 | 4.5 | NA | 1.5-10 | 89 | 4-40 | stainless steel | 452*179*140 |

| FT136 | 1.5 | 6.0 | NA | 1.5-10 | 89 | 4-40 | stainless steel | 516*198*140 |

- Required inlet temperature: 4-40°, indoor use only

- Required inlet pressure: 1.5-16Bar, pressurized valve or pressure reducing valve must be installed if pressure limitations are exceeded or fall short

- Allow for a five-hole socket and floor drain at installation place (Power supply reserved for fully-automatic unit)